What do high rise buildings, kitchen appliances, cars, and planes all have in common? If you answered “welding,” you’re right! If you have an interest in building and/or repairing the items essential for our modern lives, then the welding program is a hot choice!

Allan Hancock College’s welding technology program gives students the hands-on training they need to master the techniques used in modern welding and metalwork. Whether you are a beginning student or an industrial professional looking to improve your expertise, the welding program gives students valuable skills for personal growth and to enter or advance a career in welding.

The program provides practical hands-on instruction, taught by industry professionals using state-of-the-art welding equipment and technology. Courses focus on oxyacetylene welding, brass brazing, flame cutting, electric arc processes, blacksmithing, and much more. Upon completion, students are prepared to take additional certification exams from the American Welding Society if they choose.

Graduates are prepared for entry-level careers as a welder, welder mechanic, maintenance welder, construction welder, pipe welder, and/or welding inspector.

This program will help you to:

- function safely in a welding facility

- develop your technical knowledge and skills in multiple welding techniques

- learn how to cut metal using thermal and non-thermal methods (such as industrial size shears, semi-automatic, and manual torch cutting)

- be able to do basic layout, fitting, and cutting operations

- learn Computer Numerical Control (CNC) and manual plasma cutting

- have competency in blueprint reading

- operate a welding robot

- learn how to cut fit and bend to lay out and fabricate useful products

- pass at least one welder qualification test (3G-verticle or 4G-overhead) using at least one basic process

- pass the GMAW and SMAW processes to the American Welding Societies D1.1 Structural Welding Code

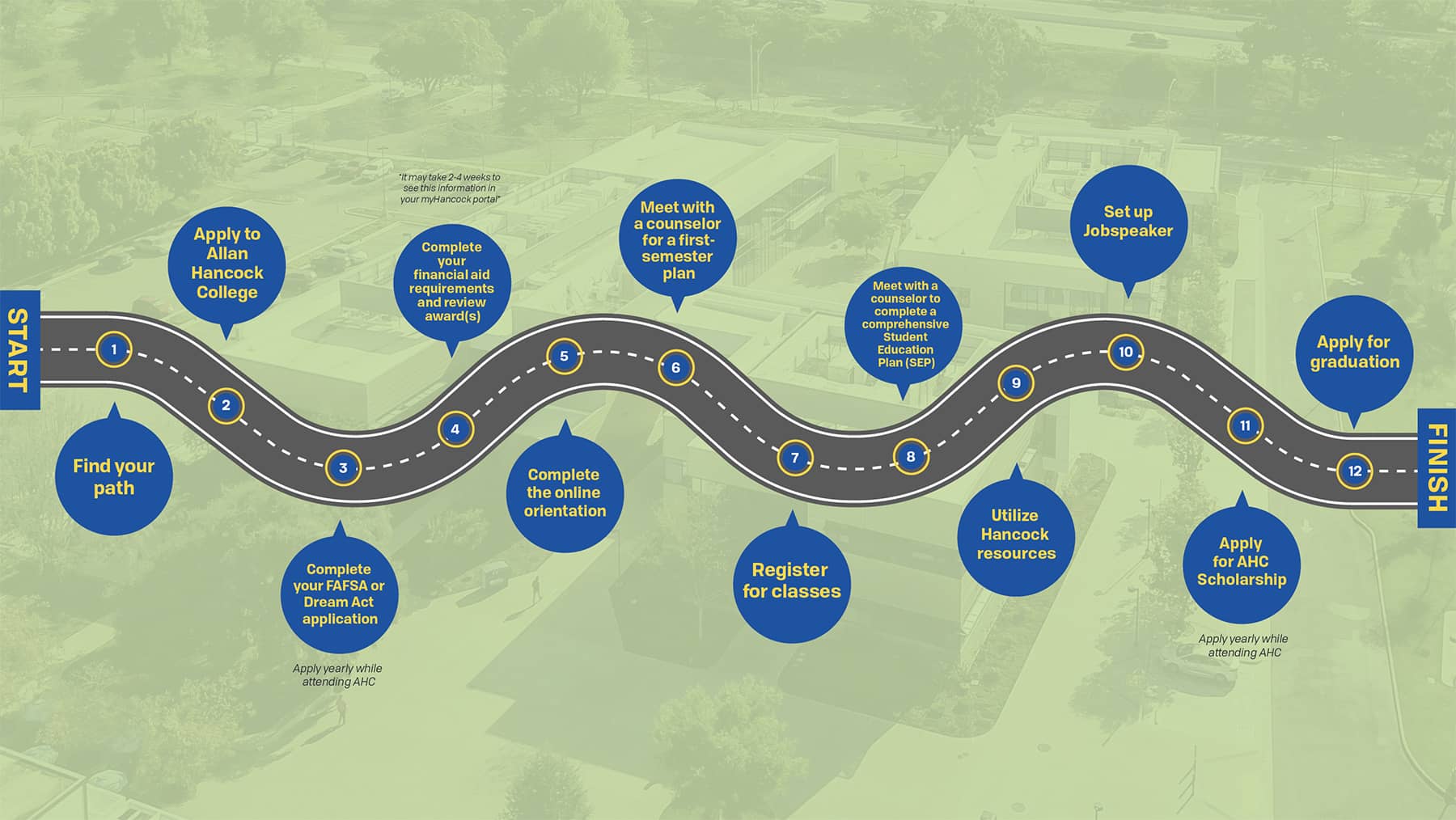

Degrees and Certificates Offered

Each program has unique requirements. The order in which you take courses may affect your completion time. Visit the links below to view the program requirements and a general semester-by-semester course schedule.

Associate in Science- Welding Technology

Certificate of Achievement- Welding: Metal Fabrication

Certificate of Achievement- Welding: Pipe Welding Technology

Certificate of Achievement- Welding Technology

To view all available degrees and certificates visit the Allan Hancock College course catalog.

Programs you may also be interested in exploring:

Contact Information

Administrative Assistant II

Alyssa Alvarez

805-922-6966 ext. 3335

Department Chair

Saad Sadig

805-922-6966 ext. 3488

ssadig@hancockcollege.edu

Dean, Academic Affairs

Thomas Lamica

805-922-6966 ext. 3261

thomas.lamica@hancockcollege.edu

LOCATION

Santa Maria Campus

Bldg. O, Room 101

805-922-6966 ext. 3335